Membrane gas separation modules

Types of membrane gas separation modules

The core component of a membrane module is a membrane element (cartridge).

Below you can find definitions of the terms, applied in gas separation.

Below you can find definitions of the terms, applied in gas separation.

Membrane –

a thin gas separation layer, separating gases due to difference of their permeability rates. A membrane can be flat or made of hollow fiber.

Membrane module –

A membrane shaped into a cartridge structure arranged in a special shell, which is instrumental to the gas separation process.

Depending on the structure of the membrane cartridge, membrane modules are available based on flat, roll or hollow - fiber membranes.

Depending on the structure of the membrane cartridge, membrane modules are available based on flat, roll or hollow - fiber membranes.

Membrane modules assembled into a single structure are called

membrane gas separation assembly

Our Company works with manufacturers of membrane cartridges, which are well - reputed in the international gas separation market.

The principle of membrane gas separation is based on different rates of gas mixture components permeation through the selective layer of the membrane due to difference of partial pressures on both sides of the membrane.

Properties of the membrane provide for unnecessary components of the gas mixture passing through the membrane gas separation layer, while the necessary components are retained.

Properties of the membrane provide for unnecessary components of the gas mixture passing through the membrane gas separation layer, while the necessary components are retained.

Permeate

H2O

H2S

CO2

C3+

H2O

H2S

CO2

C3+

Treated gas

(Retentate)

CH4

(Retentate)

CH4

Feed gas

Principles of membrane gas separation

The membrane technology is applied for separation of different mixtures. Here it should be noted that there are no universal polymers, and respectively no universal membranes applicable for efficient separation of various mixtures. Manufactures produce several types of membranes depending on composition of treated mixtures, their applications and parameters (pressure, flow rate and temperature). Each manufacturer engineers its own membranes and methods in production of membrane elements and modules. Modules from the same manufacturer may differ by the type of membrane, composition and thickness of the separation layer, and this is translated into gas separation properties of the whole membrane module.

Structural features of membrane modules

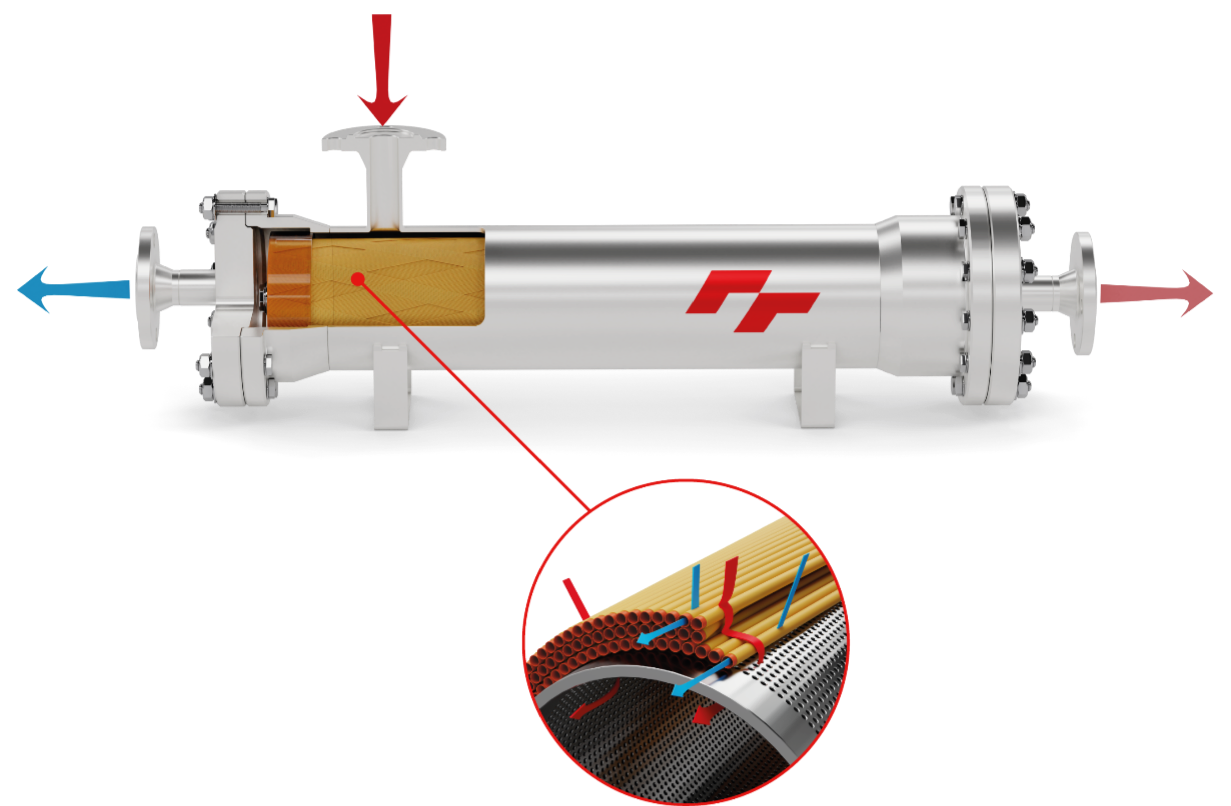

Hollow fiber membrane module

In terms of flows arrangement and the process of separation, the hollow fiber modules are divided into two types: with separated mixture flow inside the fibers, and with separated mixture flow fed into the interfiber space (please see the picture).

Separation layer of a hollow fiber membrane is always arranged on exterior surfaces of fibers.

Separation layer of a hollow fiber membrane is always arranged on exterior surfaces of fibers.

A diagram of gas flows in a hollow fiber membrane is shown on the picture. The separated gas mixture is pressure - fed into the interfiber (overmembrane) space and partially permeates inside the fibers trapping unnecessary components of the mixture (permeate). At the outlet from the overmembrane space, a mixture is produced, enriched with the required components (retentate).

Feed gas

Permeate

H2O

H2S

CO2

C3+

H2O

H2S

CO2

C3+

Treated gas

(Retentate)

CH4

(Retentate)

CH4

H2O

H2S

CO2

C3+

H2S

CO2

C3+

CH4

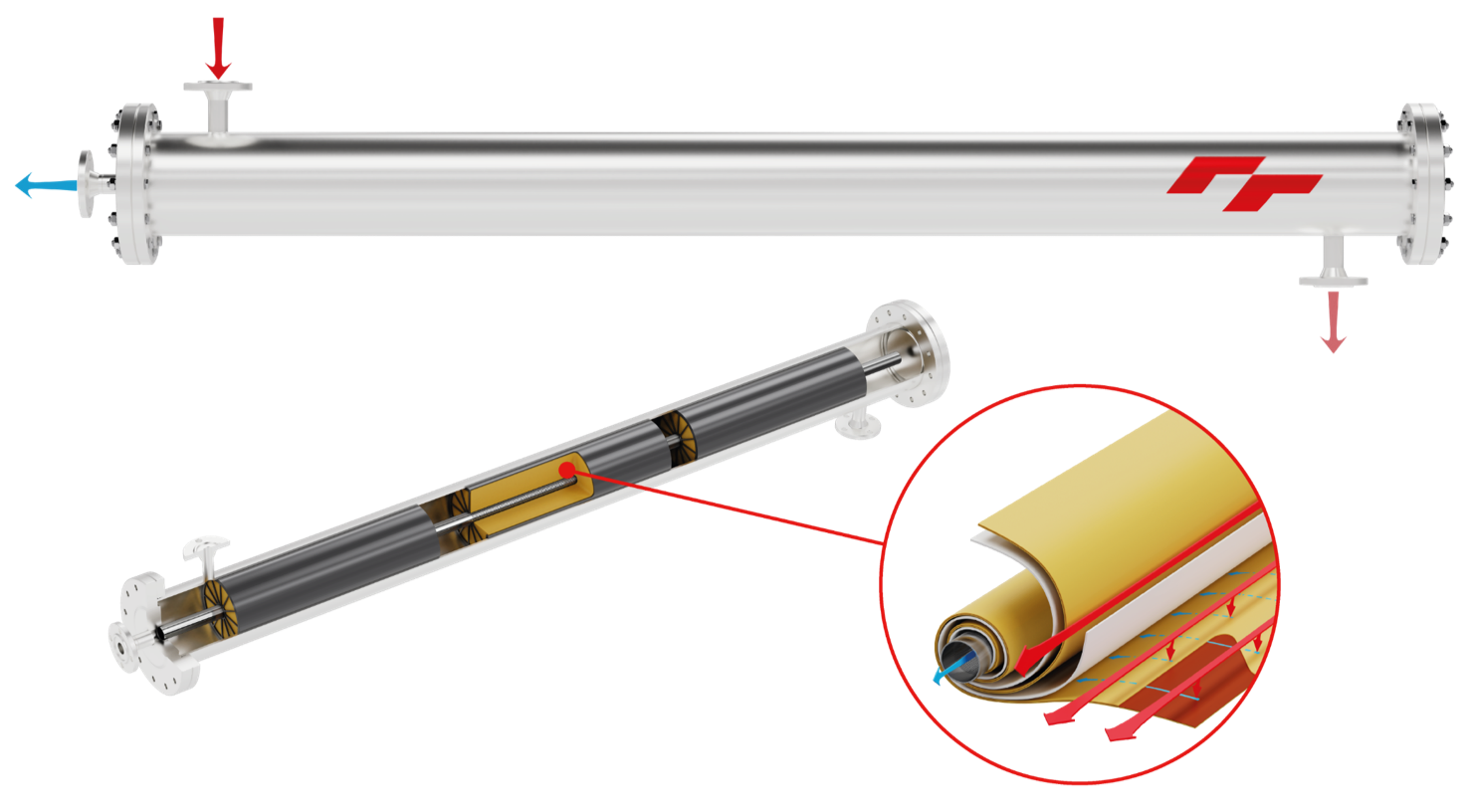

Roll membrane elements

They consist of two flexible parts. The basic part of the element is a gas - permeable membrane. Another part is a support layer to the membrane applied for separation of permeated flows of gas and the processed mixture. The membrane together with the flexible support layer are wound onto a perforated header, which intakes the gas flow which permeated the membrane (permeate). The wound roll element is incorporated into a shell. The structural design of roll membrane elements provides for incorporation of several membrane cartridges into a single housing.

Feed gas

Permeate

H2O

H2S

CO2

C3+

H2O

H2S

CO2

C3+

Treated gas

(Retentate)

CH4

(Retentate)

CH4

H2O

H2S

CO2

C3+

H2S

CO2

C3+

CH4

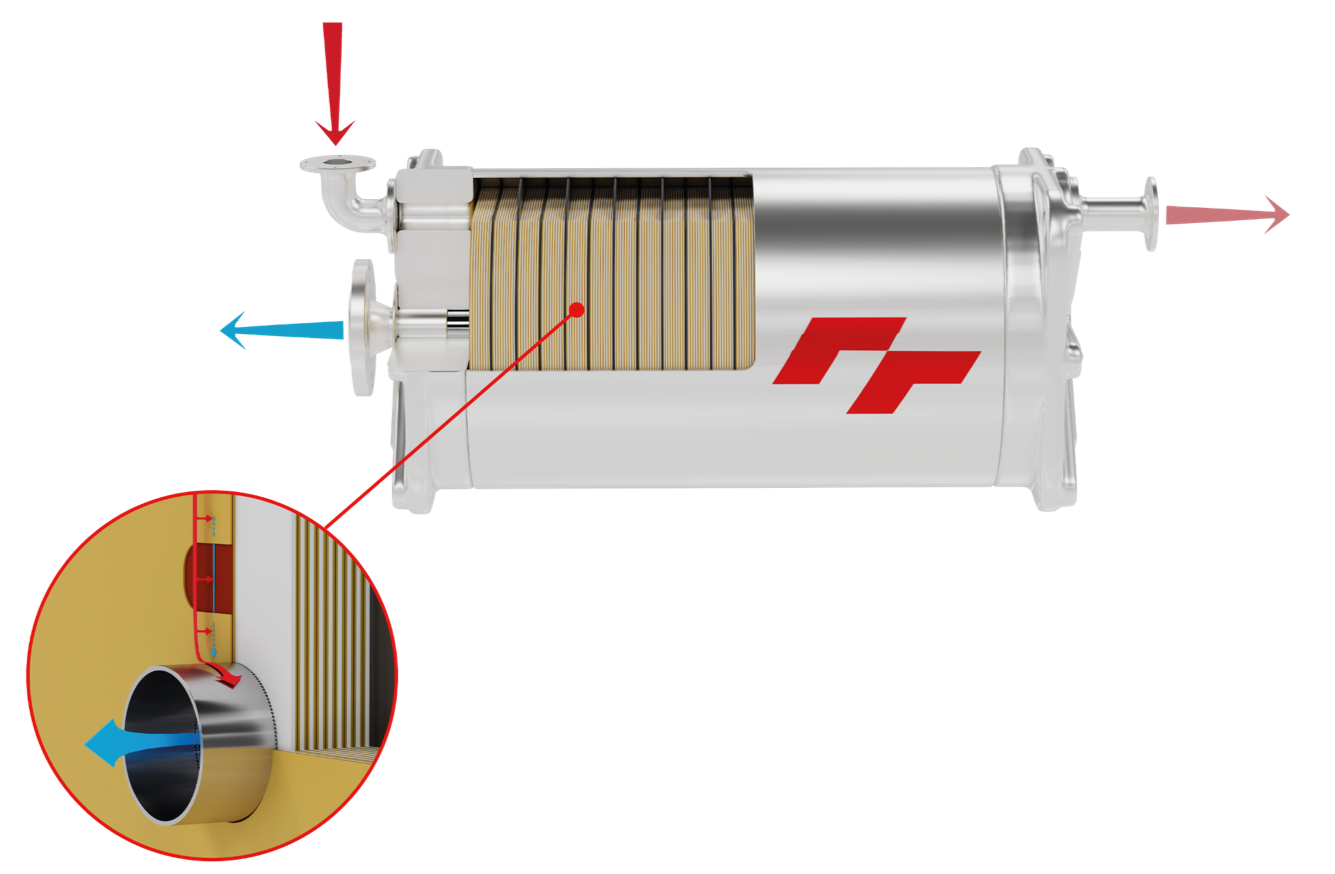

Flat (envelope-shaped) membrane elements

Membrane elements consist of a porous support layer and membranes placed on its both sides and sealed all round. There are orifices in central parts of the elements. The elements are strung on a perforated pipe and sealed. The membrane elements are separated with spacers. The whole structure is incorporated into a flanged housing.

Feed gas

Permeate

H2O

H2S

CO2

C3+

H2O

H2S

CO2

C3+

Treated gas

(Retentate)

CH4

(Retentate)

CH4

CH4

H2O

H2S

CO2

C3+

H2S

CO2

C3+

Do you need membrane gas separation modules?

Please leave your request and within 14 days we shall prepare a comprehensive technical/ commercial proposal for you

Please leave your request and within 14 days we shall prepare a comprehensive technical/ commercial proposal for you

Our Contact Details

Please write or call us, we shall provide our recommendations on any issue.

107023, Moscow, Per. Mazhorov, 8, Bld. 2

*

*

Plant configurations

Equipment

Contact details

- +7 (495) 123-34-70

- 107023, Moscow,

- Per. Mazhorov, 8, Bld. 2

Leave your request and get our free recommendations on different options available for your objective

Please leave your request and within 14 days we shall prepare a comprehensive technical/ commercial proposal for you

Give us your task and we shall provide you with different options available for its implementation

Ask your question

Write your phone number and we shall contact you in short time

We need your opinion regarding the information published on the site.

Tell us your opinion how to make our site more interesting and useful for you.

Tell us your opinion how to make our site more interesting and useful for you.